welding techniques

Welding plastics

KLV uses various welding techniques for welding plastics. Depending on the type of plastic and method of construction, we apply the following welding techniques:

- Mirror welding or stub welding

- Extrusion welding

- Torch welding or welding pen

- Stub welding

Safe and good welding

With all welding techniques, we can weld polyethylene (PE, LDPE, HDPE) as well as polypropylene (PP). All these materials can be welded in a safe and environmentally friendly way.

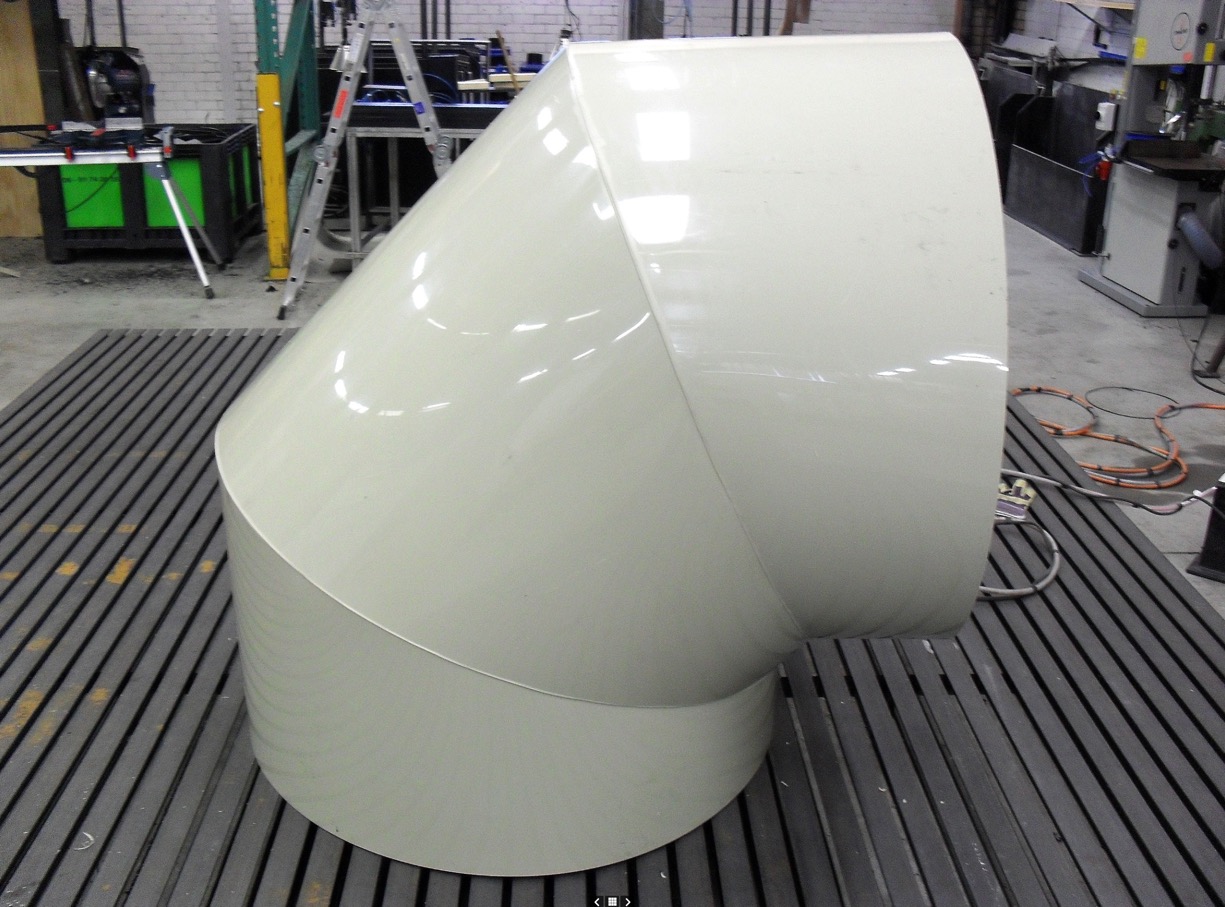

A wide variety of plastic products have been manufactured for our clients over the years. With specific wishes in execution almost every time.

Our pillars are

- advice on the right materials and techniques

- materials and raw materials of the highest quality

- extensive experience with the right welding techniques

- perfect translation from design to product

Every order is different. The use of materials such as polyethene (PE) and polypropylene (PP) enables us to meet almost all needs and any legal requirements.

We work with the most modern and accurate equipment:

- CNC milling machine (11.5m flatbed)

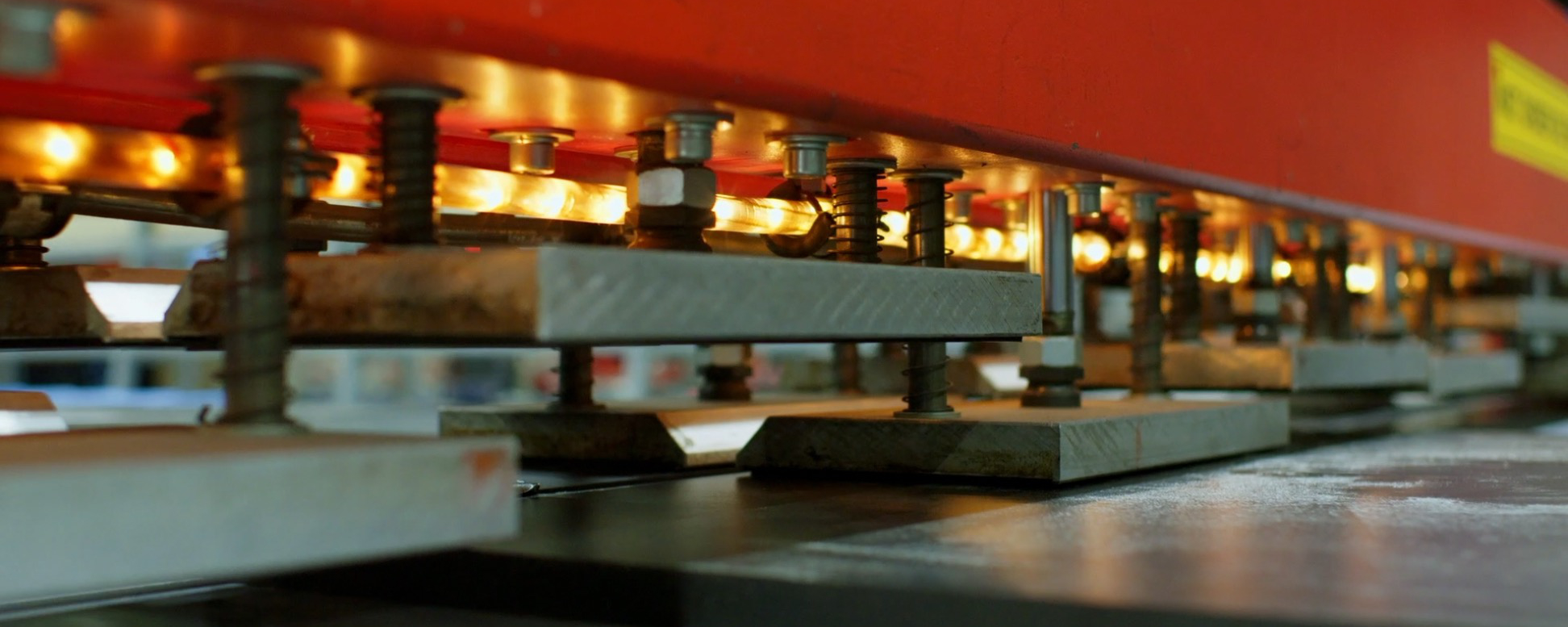

- Automatic mirror welding machine

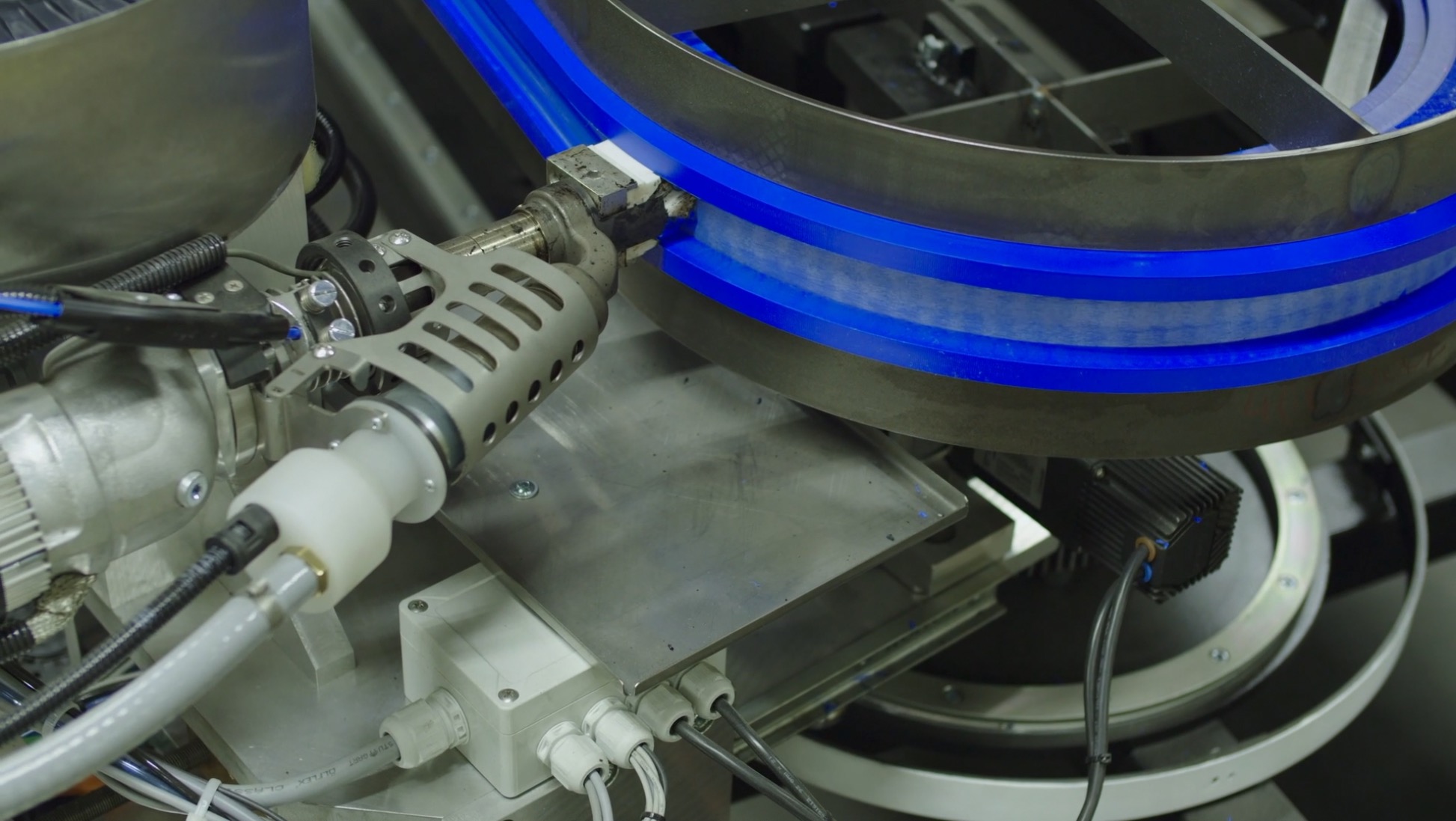

- Fully automatic extrusion welding robot

DVS is the abbreviation for Deutscher Verband für Schweissen und verwandte Verfahren. This certification is the leading standard for plastic welding. DVS certification guarantees the quality of our products.

The welds in our products are as tough and strong as the rest of the product. Our welders work according to international standards for clean and safe welding.

In mirror welding, two plastic parts are welded together by fusion. The welding mirror heats up both sides of the plastic material, after which the mirror is removed and the two parts are forcefully pressed together. In the cooling process that follows the molecules of one part and the other form a single entity.

In mirror welding, no welding agent or welding wire is used. Mirror welding is suitable for welding plastic pipes as well as plastic sheets. Mirror welding is also known as stub welding. We use a specific stub-welding machine for pipe welding.

In extrusion welding, a heated welding wire is inserted between two plastic parts using a special plastic welding device, the welding extruder. Therefore, extrusion welding is a manual process and thus very similar to welding metals with a welding electrode.

The welding wire is of the same material as the 2 plastic parts to be welded together. For example, there are polyethylene and polypropylene welding wires. Extrusion welding is mainly used when welding special joints or in hard-to-reach places. Extrusion welding is true craftsmanship.

Extrusion welding is the preferred welding method when, for example, mirror welding is not possible. For non-standard constructions, special welds and hard-to-reach places, extrusion welding is a perfect solution for plastic welding.

There are 2 ways of welding plastics with a hair dryer. For small welds or repairs, often only the torch part is used, which melts the 2 plastic parts together by heating. We then refer to this as bonding, whereby 2 plastic parts are bonded together under light pressure without the addition of welding wire. An attachment nozzle is then fitted to the welding pen.

For a firmer weld, a welding nozzle is fitted that allows use of a welding wire. This welding wire consists of the same material as the plastic parts to be welded. Plastic welding with the special welding torch is suitable for all thermoplastics such as PE, LDPE, HDPE, PP and PVC.

Cookie & Privacy informatie

Leveringsvoorwaarden

Chamber of Commerce NL #17113893

Plastic Welding Technology Verbakel works

according to the DVS-2212 industrial standard.

Omdat mensen regelmatig het woord kunstoflassen typen in plaats van kunststoflassen schrijven we hier het woord kunstoflassen bewust verkeerd zodat onze website in de zoekmachine met kunstoflassen tóch wordt gevonden! En of u nu kunstof lassen als losse woorden of kunstoflassen als één woord schrijft, we hopen dat het werkt!

Cookie & Privacy informatie

Leveringsvoorwaarden

Chamber of Commerce NL #17113893

Plastic Welding Technology Verbakel works

according to the DVS-2212 industrial standard.

Omdat mensen regelmatig het woord kunstoflassen typen in plaats van kunststoflassen schrijven we hier het woord kunstoflassen bewust verkeerd zodat onze website in de zoekmachine met kunstoflassen tóch wordt gevonden! En of u nu kunstof lassen als losse woorden of kunstoflassen als één woord schrijft, we hopen dat het werkt!